Series BTW

- throughput measurement on the loss-in-weight principle

- - for extruder control

- - for continuous gravimetric blending

- material free-flowing pellets, regrind, powder

- range: 0,1 ... 2.000 kg/h

GraviSys-g/m

Weight-per-meter control is a key process feature in extrusion lines for high-quality blown film manufacturing. GraviSys-g/m is an ideal solution either forinitial equipment or forrefurbishment or retrofit of a blown film line. The individual system components are:

- Weigh hopper

- Loss-in-weight controller GraviMaster 2408

- Siemens PLC S7-1200 and HMI

More to initial equipment ...or to ... retrofit

Gravimetric Continuous Blenders Series GCB

For gravimetric blending in high quality of free-flowing pellets, regrind or powder we offer modular units:

- standard: 1 ... 5 components

- weigh hopper Series BTW: 2 ... 100l

- screw feeder, each: 0,1 ... 1000kg/h

- vibration feeder: 1 ... 400kg/h

- control unit: compact stand-alone unit or peripheral unit linked via Profibus/ Profinet

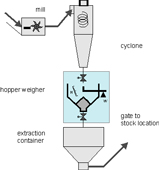

CTW

The batch weigher CTW is determined as discontinuously totalizing automatic weighing instrument to totalize the throughput of regrind, regranulate or other solid bulk material with the following properties:

- operating range: 500...5.000kg/h

- stand-alone or system integrated operation

- adaption to variable bulk density

- application area: bulk material processing, injection moulding, extrusion

- PLC: Simatic S7-1200 with Siwarex

The hopper weigher is also suited for batch-blending applications with a throughput up to 4,000kg/h.